The Inside Scoop on Creating an Epic Indoor Skate Bowl with OC Ramps

During the spring of 2023, a customer contacted us seeking information about skateboard bowls.

The customer had seen one of our recent bowls that we built in Aspen Colorado (check out the project here). We then set up an appointment to speak with a client at his property in Costa Mesa, California. Generally we don’t need to go to the clients house to view the space but in this particular case, Costa Mesa is only five minutes from our warehouse so we figured it would be easier + smoother, talking face-to-face at the location of this potential ramp build. The owner Tyler scheduled an appointment with a client and met the client at his warehouse where he wanted to put this bowl.

The warehouse was a secondary location for his business. The offices would be used in the front however, the back warehouse had some space roughly 30 x 30'. We measured where a bowl could go and the dimensions came out to 27 feet wide by 30 feet long. It was a perfect fit. There was also a rollup door that we could pull up for loading and unloading of materials.

The client expressed that he wanted this ramp to be good for beginners on up to more advanced skateboarders. His son was roughly between 8-10 years old and getting into skateboarding. The client thought this would be a great activity to do both father and son.

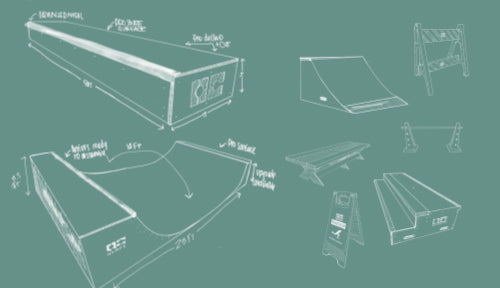

After the meeting Tyler went back to the office and started coming up with designs and optional features that could be added to the ramp. The client decided to go with a 3 1/2 foot tall ramp with a 5 foot tall extension and decided to put the five tall extension up against the wall so that way a skater could do foot plants or eventually we could add another extension to turn it into a wall ride.

Even though the ramp was going indoors, the client did want to opt in on a premium skate surface, like GatorSkins. Also wanted to have one side of the ramp with an extended deck platform just to make it more comfortable for the skaters to hang out as they wait to drop in.

With the greenlight and deposit, we started the preparation starting with the bowl corners at the shop. As we mentioned in previous posts, skate bowl corners are extremely tedious and time consuming. It takes several weeks for us to complete the bowl corners. From there we start prefab being everything else for example, pre-cutting the two by fours pre-drilling, the plywood countersinking the Gator Skins sheets, etc.

On the day of the installation, we showed up with a trailer full of materials and pre-built corners. We had about six workers and fortunately one of the neighbors at the property had a forklift. We then asked the neighbors if we could buy them some beer in exchange for unloading the corners with their forklift. They agreed!

As we continued with building out the mini ramps, pushing the ball corners together, and then welding all the coping pieces in place by the end of day. One all the framing was done. The coping was complete and the first layer of plywood was done.

On day two we finished with plywood, extending the platform and sheeting the ramp with Gatorskins.

A few of our pro skaters came through that afternoon as we were cleaning up. They were anxious to skate this bowl.

The client came out to watch Mike Berdis and Kayden shred the bowl. Mike was battling a foot plant on the wall while Kayden was pumping around having a blast. Pro tested and approved!

We are very proud of our team that was able to complete this bowl installation within two days - that’s a record! Even better, the client was super stoked on his newest skate bowl addition. If you’re looking to put a bowl in your backyard or warehouse, make sure you at least have 30’ x 30’ and give us a call!