Wood Skateboard Bowl with Skatelite and Skatepaint

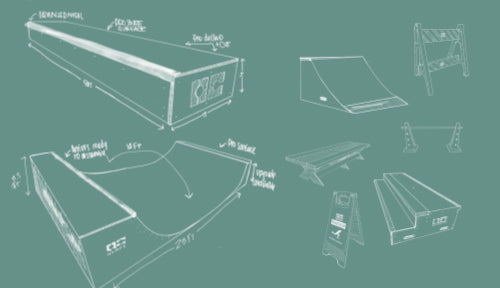

We have been in contact with a customer for about a year now, he expressed interest in wanting a custom wooden skate bowl in his new backyard. This customer has been working on building a custom house, adding in a pool in the backyard, as well as a full basketball court and a lounge area. In the process of relandscaping everything, he made sure to leave the perfect spot for his custom bowl. After finalizing the dimensions of the space we had to work with, we began designing the perfect product. We began building with the bowl corners, this is the absolute most difficult part of building any bowl. There are beveled cuts, compound cuts, and hundreds of pieces that must be installed. In addition to all of this, OC Ramps only uses screws in building these custom bowls. The few companies that also build bowls tend to use nails to speed up the process, we take our time with it and make sure that we only use rust proof screws with everything to ensure our customer gets the best product possible. The build crew made sure all the cuts were perfect so there were no gaps in any of the corners. It took the warehouse several weeks just to finish and perfect these pieces! When the corners were ready, we framed out the rest of the ramp and we had our freight company bring their 53 foot long semi-truck and we filled it to the MAX with the ramp pieces.

We have been in contact with a customer for about a year now, he expressed interest in wanting a custom wooden skate bowl in his new backyard. This customer has been working on building a custom house, adding in a pool in the backyard, as well as a full basketball court and a lounge area. In the process of relandscaping everything, he made sure to leave the perfect spot for his custom bowl. After finalizing the dimensions of the space we had to work with, we began designing the perfect product. We began building with the bowl corners, this is the absolute most difficult part of building any bowl. There are beveled cuts, compound cuts, and hundreds of pieces that must be installed. In addition to all of this, OC Ramps only uses screws in building these custom bowls. The few companies that also build bowls tend to use nails to speed up the process, we take our time with it and make sure that we only use rust proof screws with everything to ensure our customer gets the best product possible. The build crew made sure all the cuts were perfect so there were no gaps in any of the corners. It took the warehouse several weeks just to finish and perfect these pieces! When the corners were ready, we framed out the rest of the ramp and we had our freight company bring their 53 foot long semi-truck and we filled it to the MAX with the ramp pieces.

We drove up behind the freight truck all the way to the bay area. Once the ramp pieces were unloaded we set up pavers, and began to assemble the ramp on top of these pavers. The reason that we chose pavers was to elevate it elevate it a couple inches to make it level, and also to make sure it was not sitting in dirt or grass. This is in order to make sure that when it rains that the ramp is not sitting in any mud. Pavers are highly recommended for any bowl or mini ramp because they really help to prolong the life of the ramp. Once the team finished assembling the frame of the ramp, they began to lay in the coping. Before the build crew headed up to the build, they had bent the pieces of coping into shape, so now we just needed to weld it into place. We brought our welder and welded all the coping pieces together to make it as seamless as possible. After the welding was finished, the crew waited for the pipe to cool down, and then proceeded to paint the coping.

The next step was to start sheeting the ramp. First, the team did a base layer of plywood, and then they installed the top surface of skatelite pro. It took us several days to complete the installation, working 12 hour days until sunset each night. Once the ramp was complete, we coated the top decks and back ends of the ramp with skatepaint. It is important to note that you NEVER want to apply any paint to the skatelite surface itself, so obviously in this build the skatelite surface remained untouched by paint.

Once this massive project was finished, the customer came out and was ecstatic with the results, it was like watching a little kid on Christmas!

Throughout the entire build process, a lot of his friends and neighbors would stop by and check out how things were coming along, and everyone was stoked for it to be completed.

Before taking off, we skated for a few minutes and had a blast. This is by far one of the most fun ramps that we have built to date.

This customer also has a huge tree near the ramp, we suggested that they should add a treehouse with a ladder from the platform to the house, the customer loved the idea.. so who knows, we may head up there soon to set up a treehouse for them too!

Skate bowls are an extremely difficult thing to build, we don't offer them in kit form because every piece has to have a custom fit. However, if you are interested in having a skate bowl in your backyard, or for commercial use feel free to contact us here at OC Ramps, as we are the leading ramp specialists! We do installations from Orange County, all the way across the US. For more info call us or fill out a contact us form, which can be found here.