Spine Ramp for Shaun White

Hot & Sunny Nevada

We have had a relationship with Shaun White for a number of years. We first worked with him around 5 years ago when we removed an old ramp from his property in Los Angeles, California.

We have had a relationship with Shaun White for a number of years. We first worked with him around 5 years ago when we removed an old ramp from his property in Los Angeles, California. We also helped set up some ramps for an art exhibit for his Air & Style show in Los Angeles, California. It was also during this time in which he mentioned that he was wanting to get a ramp set up at his house out in Nevada.

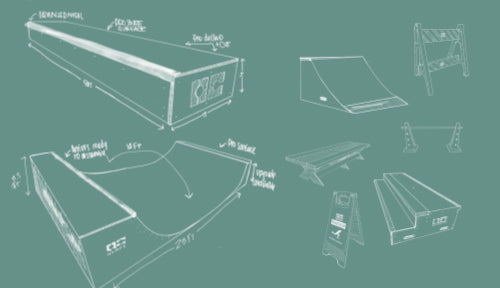

We went back and forth over the years trying to figure out what he wanted to do and the location of where he would like the ramp set up. Over Spring 2021, he decided that he wanted to go with a 4 ft tall x 16 ft wide mini spine ramp. A spine ramp, in essence, is two half pipes (or mini ramps) that are placed together without a platform in the middle. A true spine ramp will have two copings in the middle.

He wanted to use a premium skating surface for the spine ramp. We reached out to Skatelite directly who offered to sponsor the ramp and provided these sheets at no cost for Shaun. Skatelite sheets are professional grade and durable paper composite material which many use as the top skate surface for skateboard ramps. These sheets strengthen the integrity of the ramp and protect it from the wear and tear which comes with weather.

Once the type of ramp and materials to be used were settled, Shaun emailed us over a few photos of the space where he wanted the ramp to go. He had a couple of trees and bushes that were in the way of where the ramp was going to be set up and the ground was not completely level. Since Shaun is not local to the OC Ramps warehouse, we asked that he had his own crew prepare the foundation at his location in terms of everything being level.

The length of the spine ramp was just going to be shy of 50 ft so he had to make sure that he had at least 16 ft width and 50 ft length of a flat, level surface for the ramp to sit on. He hired a couple landscapers to remove the trees and bushes along with flattening everything out as best as they could to prepare for the installation. We then requested that Shaun send us footage from his driveway to the build site so that we had an idea of the space available for the trailer and also determine if we were to arrive with partially built parts, would they fit through the walkway.

Once we ironed out all of the kinks, we began with the fabrication of his skateboard ramp at our facility in Orange County, California. We had to first start with the CNC design and getting the cut of the radius and coping cutouts perfect. We cut a few sheets of plywood on our CNC machine to first test. We wanted to make sure the transition was just right and wanted to make sure that the coping sat in perfect and would not stick out too far nor be too recessed in. After making some adjustments, we cut out all radius transition pieces on our CNC router. We then took the measurements of the 2x4 supports and starting precutting and predrilling all plywood sheets as well as the Skatelite sheets. We also prepared his coping pieces in a white color.

The next step was to securely load everything onto the trailer in preparation of a 5 hour drive. All in all, our 20 ft long trailer had about 10,000 lbs of lumber loaded onto it. The day of the trip, we connected the trailer to our Toyota Tundra and left our facility with a crew of 5. The drive took a little longer than expected and the trip ended up taking us just over 6 hours in driving because we had to drive very slow and carefully along the freeway. To portray how slow we were going, let's just say that most semi trucks were passing us along the route. Our primarily goal was not to get there rushed or quickly, we wanted to be sure we arrived safely with all 10,000 lbs and 5 crew members.

We arrived on a Monday afternoon at about 3:30 pm. We knew the sun was setting at 7 pm sharp. Due to this, we put together a game plan of tasks we wanted to complete while we were driving to our destination. Our goals for the day were to unload all of the materials and to build out the frame of the ramp prior to the sun setting. The second we arrived, everyone had a task. One crew member unloaded all tools, found an electrical outlet, and set up a work station with a table, organized batteries, chargers, and drill bits. Another two guys were unloading the partially assembled pieces while the remaining two organized the numbered sheets of plywood and other lumber.

7 o'clock came up faster than expected, but we were able to reach our goals for the day. We would have liked to work a little longer except that sun went down quick and the dark set in pretty fast. After the day's work, we were all exhausted. We went out for a good Mexican dinner where we discussed the game plan for the next day - the job never ends! Our goal for the second day was to finish whole ramp by the afternoon. The idea was to split up the group into two teams where each team would work on different sections of the mini ramp.

That following morning, we arrived and immediately went to work. We were trying to work quickly and efficiently so that we would not get fried by that hot Nevada sun.

By lunchtime, we were done with several sheets of Skatelite so we knew that we were going to be able to reach our goal of finishing the spine ramp by mid-afternoon. The most difficult part was attaching the two copings to the middle section of the spine ramp. With the tons for tools we brought, we did not have the right bit to drill into the coping so went sent one of the guys on our build crew over to Lowes to purchase the correct bit. We ended up securing the copings through an old school method of drilling a bigger hole at the top of the coping and then drilling the screw through that opening that would suck down into the lower 2x4. This was a method of securing most copings to any skateboard ramp in the 80's and 90's, but it is certainly most applicable to even a modern day spine ramp.

The ramp was completed before 3 pm. TomTom was there with us and was anxious to grab his skateboard and do a couple of stretches before hopping on the ramp. Even under the blistering sun, Tom could not wait to skate. He did his first run, grinding through all sections of the ramp with a huge smile on his face. He could not stop mentioning how fun these spine ramps are. A lot of skaters that are in their 30's and 40's now grew up skating a spine ramp.

We took our photos and several videos of Tom shredding the new ramp. Shaun’s photographer came out to see us and also capture some footage. Meanwhile, he was able to FaceTime Shaun so he could see how the ramp turned out. Shaun was beaming and was super stoked after seeing Tom do the run. He was thrilled and could not wait to get out there. He was like a kid who got a present at Christmas and wanted to play with it right away.

After taking all photos and video, we cleaned up our area. One guy walks around with a magnet to pick up all additional screw hardware while another guy was loading up the trailer with any extra materials. We often travel with extra materials in case something does break or needs to be replaced. By the time we packed everything up it was about 4 pm. We left the trailer there for the evening and went to our hotel to celebrate, swim, and eat some BBQ. We also could not leave Nevada without checking out the Las Vegas Strip and Fremont Street.

After all, the crew did deserve a break after working so hard and efficiently.

The next morning, we went and picked up our trailer and hit the road. Fortunately, we were able to drive a little bit quicker on the way home with a lesser load. We got back to OC Ramps within 4 and a half hours, unloaded, and called it a day.

All in all, the trip went extremely smooth. This is the nature of our business. It all boils down to proper planning and having a good team. Each member of our crew contributes something of value and every member brings something different to the table. That’s what makes these skate trips such a success.

@oc_ramps We put in work 🛠 for @shaunwhite . The amazing spine ##ramp. ##skateboarding ##diy ##work

♬ Work - Sonny Digital

Be sure to check out our TikTok for other ramp builds we have been doing! As always, please contact us with any questions. The OC Ramps Team is always happy to help!