Mini Ramp & Pump Track? Let’s Talk Backyard Skatepark Goals

The OC Ramps crew recently wrapped up a RAD custom backyard skatepark project. We met the customer through another customer who we had done a custom ramp for 10 years ago out of San Clemente, California.

After an exchange of a few emails with the customer where he sent us the dimensions of the space our crew had to work with along with images of skateparks that him and his kids enjoy skating, it became clear that they were interested in a mini ramp along with a pump track.

While brainstorming some ramp ideas for his kids, he made it clear that he wanted the ramps to not be too entry level to where more advanced skaters would get bored with or be unable to fully enjoy it.

This, for us over at OC Ramps was a perk, as this is something which we pride ourselves in. Our main goal when creating our skate ramps is that they are universal for all ages and all skill levels.

Following this, we also had to wrestle with the next step which was the foundation for the custom ramp.

The current space was a dirt lot so we were unsure as to if we were going to build on the dirt, if the customer was going to pour gravel beforehand, or if he was going to go with a cement slab. We also talked about ideas regarding cutting into his grass hill and building the half pipe so that it was level with his grass

In the end, the customer decided to pour a concrete foundation 70ft in length by just under 30ft in width. He also decided to build a retaining wall and cut into the grass hill so that the ramp platform would be level.

Building a retaining wall and cutting into the grass hill also made for an alternate way for his kids and neighborhood skaters to access the ramp. It allowed them to walk straight from the grass onto the top deck of the ramp.

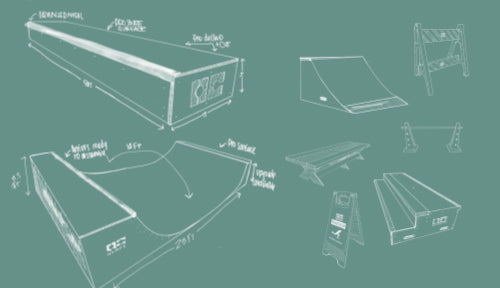

Once we knew the foundation and reviewed all of the customer ideas, we locked down the idea of building a 24 ft wide mini ramp along with a pump track.

After that, we began production at our OC Ramps facility in Orange County, California. Our goal was to try to prefabricate as much as possible prior to the installation on-site.

Our CNC designer was able to create the pump track files so that we could get exact and precise cutouts and smooth transitions.

We did a mock assembly within our warehouse to make sure that our dimensions and spacing were all exact. We then loaded our flatbed trailers with several sections already framed out and coordinated a delivery and installation time with the customer.

Our crew left on a Saturday morning from our facility and arrived in Encinitas, California at 8 am. We were able to pull all of our trailers up to the concrete foundation and began the unloading and installation process immediately.

We used Gator Skins for the top skating surface (a premium and weather resistant skating surface).

Our goal was to be done and out of there by 2 pm – we missed our goal by a few minutes but we wrapped up just before 3 pm.

Dave Bachinsky, a professional skater on our team, was there to test out this custom skatepark and ensure that it rode butter smooth. Dave had a good time doing a 10-minute demo in front of the neighborhood kids who all were cheering him on.

After our test run was complete, we packed up our tools and hit the road.

After touching base with a customer the following week to ensure he was satisfied with our work he ensured us that his house is the house of the neighborhood and they have ordered more obstacles to add to their at-home skatepark.

This was definitely a rad project for the OC Ramps crew to be part of and collaborate with our customer on some different ideas and visions he had for this at-home custom skatepark.